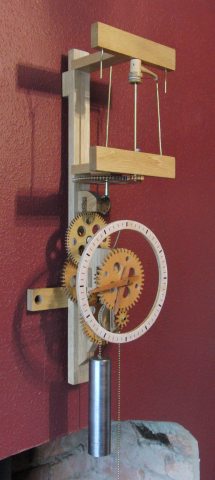

I built all the parts for a clock and assembled it, but soon discovered that getting it to run for more than a few seconds

without stopping was the real challenge of clock making. The gears had to be made extremely accurately or they would

jam and the clock would stop. This was not an easy task, especially when working with wood. I had to scrap and remake

every single gear wheel, spending many hours figuring out the problems. But eventually, it was running pretty reliably

and kept surprisingly good time.

For anyone considering making a clock, I would highly recommend it. It is very interesting and rewarding when you finally have

a working clock. However, do not underestimate the level of accuracy required for the gears and how free-running every

bearing must be. The slightest problem with a gear tooth or bearing will cause the clock to stop.

I used software to design gear wheels, which I then printed, glued to plywood, and roughly cut out on a bandsaw. I then used a

small vertical belt sander to achieve final accuracy on the gears. This is a time-consuming task but does a pretty good

job. If you can access a laser cutter or CNC router, it would be an ideal way to make the gears. Additionally, make sure

the center hole in the gear is very accurate, as it can cause problems if not done correctly. I cut the center hole

before gluing the template on and cutting the gears.

Before starting on making your first clock, I suggest first just make a pair of gears. Mount them on a piece of wood and while

applying slight resistance to one, turn the other very gently and feel for any slight resistance. The gears should turn

reliably without hesitation. This will give you a good sense of the level of accuracy required for the gears of your

clock and help you avoid some of the mistakes I made.

I used this clock for a good while but I have now replaced it with

clock number 2

(below).

Clock 2

This clock is completely my

own design; I watched a

flying pendulum or Ignatz clock

on YouTube and thought I just have to try making one

of these!

I

had no plans or anything more than a few pictures of these clocks,

so I

first set about

making the escapement

just to see if I could

figure it out, then when this seemed to work I started

adding the rest bit by bit until I had a finished clock - I think it

turned out

surprisingly well considering the lack of any real planning.

I had the idea in my head of how the top horizontal gears would take

the

drive towards the back of the clock but had no idea how I

could make

the bevel gears, I then had a flash of inspiration - I bought some

Mechano bevel gears from eBay and used those ;-)

It was then pretty simple working down the clock with the next 4

gears

(I

know the smaller ones are actually called pinions, but you know

what I mean)

I

then spent some time figuring out how the next part would work and

had

another flash of inspiration - If I put the drive pulley in the

centre

of the hour hand gears this would save me having to

make extra gears for the pulley.

It had now all fallen into place and I had a working clock ....

I have always said that the Ignatz clock is famously inaccurate (more

a

novelty than a

time

keeper)

and they often don't even bother fitting a minute hand

for this reason, mine was no exception. But recently I finally

got round to looking at tweaking my clock as the weight was

sometimes

striking the centre bar. I lightened the weight a little and I

have been amazed at the result, I think this had been upsetting the

time keeping far more than I had ever imagined. This clock is

now

keeping surprisingly good time :-)

This clock has been in use since Apr 09 with no major problems,

Occasionally I have to replace the string on the flying

pendulum as

it gets a bit frayed.

Although it looks pretty complicated I think this type

of clock would actually be a better first try at clock making as I

found it easier to get running reliably as the escapement of the

Ignatz

tends to keep things moving as it pulls the gears along as it swings

where as the more usual escapement tends to

stop the clock then it is up to the gears to start moving again on

their own accord.

I finished this clock in Apr 2009 and it has been in constant use

ever since, I had expected the gears to soon start wearing/breaking

especially with them being made of the cheapest plywood but so far

there are no visible signs of wear at all and it is still running

fine, in fact it is extremely rare for it to even stop. It can

keep reasonably good time when adjusted (these escapements were

never going to be very accurate) but this seems to vary a lot with

humidity changes, I keep meaning to try some different thread as I

suspect this is the cause...

I

don't have any plans for this clock as I designed it as I went

along, but if you email me I can send you the files I used to create

the gears etc..

Clock 3

I did plan to make another clock similar to clock2 but this time

use some decent quality wood and spend more time on getting a decent

finish as the one I have was more of a prototype and not great when

you

look at it close up - but I will probably never get round to it?

I have recently got interested again in playing with electronics

(something I did many years ago but never really did very well

with it),

I then discovered the

Arduino

microcontroller which makes it all so much simpler....I was never

very

good with analogue electronics with all the maths etc. but with the

Arduino this side can be kept

very simple and everything is done just by programming it in a

version of C so you can easily create some pretty impressive things

with it.

I have built myself a CNC router and this looks like the ideal tool for making gear wheels, it can cut one out

in under a minute which by hand would take me hours. If more info. on this would be of interest please let me

know as if there is enough interest I will supply details of how to build one cheaply and the easiest way to

use it.

e.g. To make a gear I draw one using Inkscape (it has a built in gear wheel tool) then use Laserweb to convert

this to the required gcode for my cnc router.

You

can contact me on - alanesq@disroot.org

Back

to my homepage