|

Alan's

Roboclock |

|

|

Alan's

Roboclock |

|

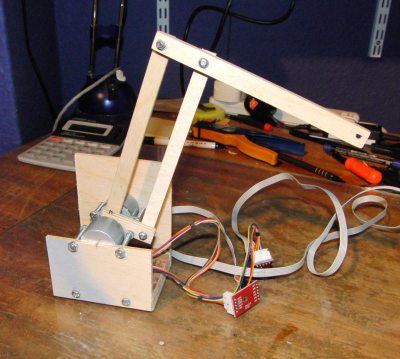

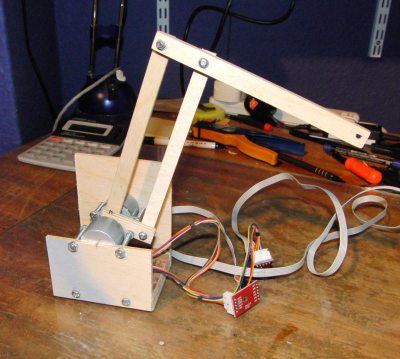

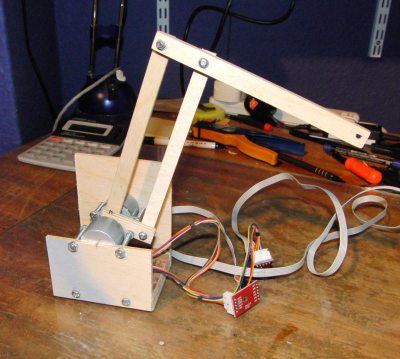

| Dec

2012: I

first tried using servos but whilst this looked promising, it turns

out that the angles servos actually move to are very non

linear and so I was unable to

get any kind of usable accuracy from them. I then had a try to

see

what I could do with a couple of cheap stepper motors (£5

for 2 from eBay including control circuits) building the

most

basic arm I could think of. This is much better, the motors have a bit of play in them (and all the joints for that matter) so there is some free play in the arm, but it is good enough to do something with and at a total cost of £5 plus a bit of wood ans some bolts, it is a good project in it's self and probably has lots of uses.... I control it with an Arduino Uno (see more info HERE) To position the arm it just requires to be given an x and y coordinate i.e. tell it to move to 100,150 and the arm will move so that it's tip is 100mm to the right and 150mm above the motors output shaft. This is where the maths came in, you can see more on how I did this HERE The arm is very easy to build, it is just two stepper motors mounted so they are facing each other with the output shafts opposite, I then turn both at the same rate to move the shoulder and one on it's own to move the elbow, very simple but works surprisingly well. The Arduino Sketch for this arm can be seen HERE In this sketch you enter the coordinates via the serial monitor (e.g. 100,120) and the arm moves to that position. - As I am learning, robotic is much more complicated than I ever imagined, so there is plenty could be improved on this - but it works....... |

|

You can contact me on - alanesq@disroot.org